Videojet 3140

10-Watt CO2 Industrial Laser Marking System for Moderate to High Speed Applications

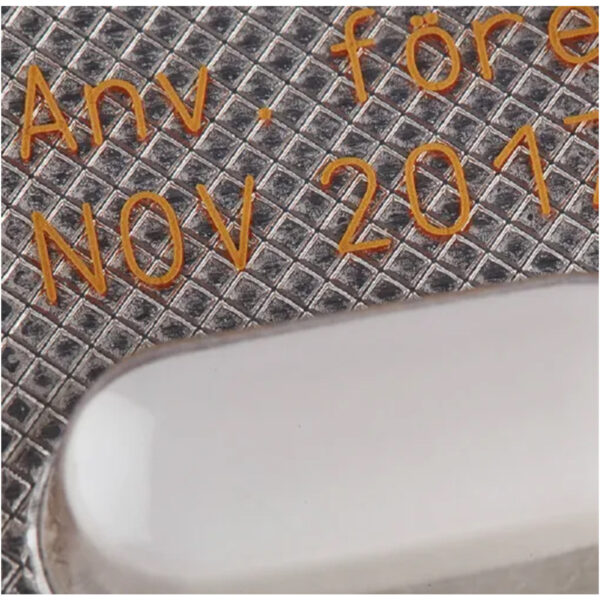

The Videojet 3140 10-Watt CO2 laser marking system is engineered to offer all of the performance features found in higher wattage Videojet lasers, but with a power source better matched for moderate line speed applications. Ideal for both simple and complex code requirements on a range of substrates including paperboard, glass, painted metal, paper labels, PET and other plastic materials. The 3140 offers flexibility to meet a broad range of applications in many food, beverage, cosmetics and pharmaceutical operations.

And with optional VideojetConnect™ Remote Service, your team can access Videojet experts to help improve productivity and troubleshoot potential issues in ways that other printers can’t.

Specs

| Value | |

| Laser Tube | CO2 |

| Maximum Power | 10W |

| Laser Cooling | Air Cooled |

| Maximum Print Speed | 2000 characters/sec |

| Maximum Line Speed | 900 m/min (2,940 ft/min) |

| Environmental Protection | IP54, 65 |

| Beam Output | Steered Beam |

| Laser Source Expected Life | 45,000 hours |

| Laser Wavelength Options | 10.6 μm, 9.3 μm |

| Focal Distance Options | 64 mm (2.50 in) – 400 mm (15.75 in) |

| Maximum Mark Window | 485 x 351 mm (19.09 x 13.81 in) |

| Standard I/O Connectivity | Internal Terminal Connections |

| Standard User Interface | Handheld |

| Optional User Interface | PC, CLARiTY™ Laser Controller, TCS, Smart Graph Com |

| Umbilical | Detachable, 3 Lengths |

| Plant Air Used | No |

| Certifications/Approvals | CE, TÜV/NRTL, FCC Compliance (no certification required): ROHS, CDRH/FDA |

Benefits

Versatile coding solution delivers high performance

- Optimized control software automatically calculates the most efficient way to mark, achieving faster marking speed

Uptime Advantage helps keep productivity up and costs down:

- Laser tube is designed with larger gas volume and system is optimized for air-cooling to provide operational life of over 45,000 hours

- Optional IP65 makes printer suitable for harsh production environments without need for plant air

- CLARiTY™ Laser Controller reduces operator errors helping to ensure products are coded correctly, and advanced productivity tools help identify the root cause of downtime events to help make sustainable process improvements

Engineered to precisely match your exact coding needs and integration requirements:

- Two available laser wavelengths, three marking heads and thirteen lenses for optimal code quality on your specific materials

- 32 standard beam delivery options for integrating the laser marking system into your packaging or filling equipment can help produce the best system uptime

- Multiple communication options designed to help integrate the laser marking system into many different control systems

- Detachable umbilical available in 3 lengths for easy integration and line changeover, plus focus finder tool for quick set up of accurate focal distance

Q & A

Sign Up to Newsletter

Quick Links

Inspired Innovative Solutions

We strongly believe in the formation of effective lasting partnerships with our clients.

Reviews

There are no reviews yet